Pioneers in plant and equipment manufacturing

Unmatched products for the sugar industry

For over half a century, we have been supplying top of the line equipment for the sugar industry around the globe. With our experience and expertise of the sugar manufacturing sector, we also provide our customers with turnkey solutions and consultancy to help enhance their operational efficiency, increase productivity and minimize costs. With over 100 years of engineering experience and expertise, Qadri Group is the right choice when it comes to setup or upgrade your sugar manufacturing operations anywhere in the world.

Technology Partners

FRANCE Technology Partner Sugar

CZECH REPUBLIC Technology Partner Sugar

Services We Offer to the Sugar Sector

Qadri Group is a trusted name in the global sugar processing equipment industry. We not only produce state of the art equipment and products but provide complete turnkey solutions, consultancy and project management to help our clients enhance and maximize their manufacturing efficiency.

Consultancy

With our knowledge of the global sugar manufacturing industry, we are able to help our clients identify critical issues and realize opportunities that ensure growth.

Plant Upgradation

By providing latest design, products and spares, we can help you set up new or upgrade your existing sugar manufacturing operations to outmatch your competition.

Case Study / Audit

Using our experience, knowledge and key insights from successful projects in the past, we can guarantee success by applying valuable findings from similar projects.

Equipment

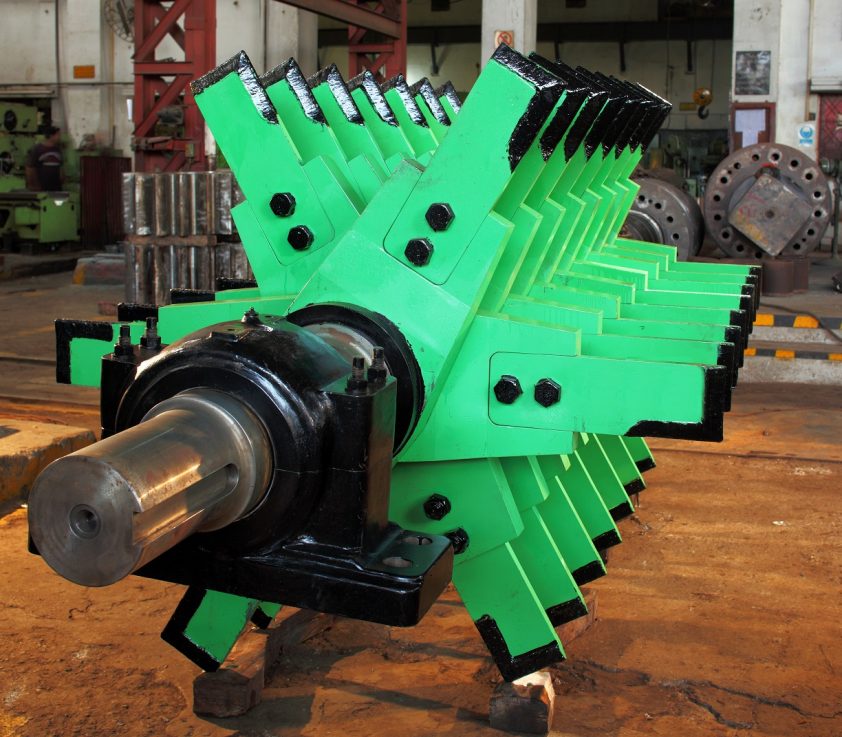

Cane Preparation

( capacity up to 25,000 TCD )

Overview:

The Cane Knife Assembly is used to chop Sugar Cane from the Feeding Table, It is directly installed on the main cane carrier mostly in sets of primary and secondary .

Salient features

Proven Rugged Design

– Primary knife stagger angle is 120°

– Secondary knife stagger angle is 60°

– Installation of primary and secondary knife sets make sure continuous act upon the stream of cane stalk

– Replacement of knife is very easy

– Installed with heavy-duty self-aligning roller bearings

High Efficiency

– Swing dia. 1676 mm helps to achieve recommended tip-velocity 60 m/sec at low rpm.

– Combination of primary & secondary knife sets helps to achieve 60 ~ 70 PI which will substantially increase the performance & efficiency of the shredder.

Recommended Installed Power

– Primary knife set ……..… 15 kWh / ton of fiber

– Secondary knife set …..… 30 kWh / ton of fiber

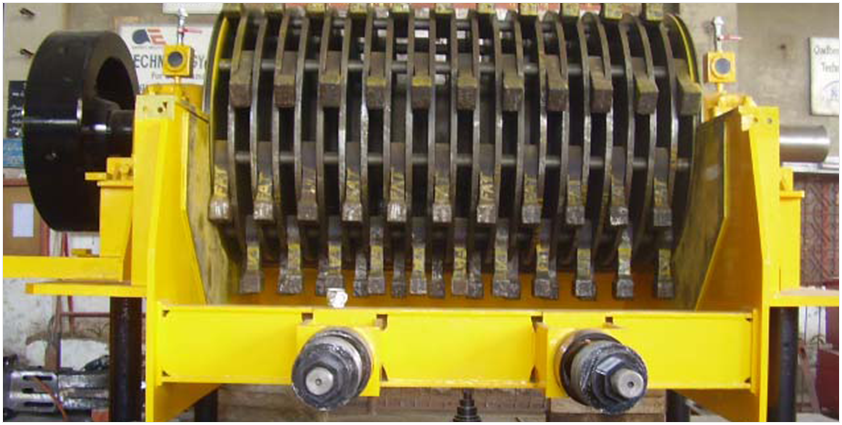

Cane Preparation

(Capacity up to 25,000 TCD)

Overview:

It is the top fed shredder in which cane enters from the top and exit from the bottom . Shredding is done multiple stages at each stage clearance is reduce between hammers and anvil bars , resulting in open cells of cane at discharge opening.

Salient features

High efficiency and high capacity

– Excellent fiber particle size distribution.

– Extremely robust fabricated assembly.

– Excellent cane preparation index (90+).

– Improved final bagasse moisture.

– Better feeding of the mills.

– Consistent higher bagasse density.

– Lower bagasse pol loss.

Proven technology

– Fine preparation by separating the fibers and opening the cell wall efficiently.

– Excellent juice extraction at each stage of extraction process.

– Increases bulk density of the prepared cane, thereby increasing the capacity of the extraction plant.

– Easy to maintain.

Mechanical and cost effective

– Cost effective & reliable solution.

Flexible & Complete Offer

– A wide range of technical & design services available to optimize cane preparation system to meet customer’s need.

– Portfolio includes a large range of shredder size.

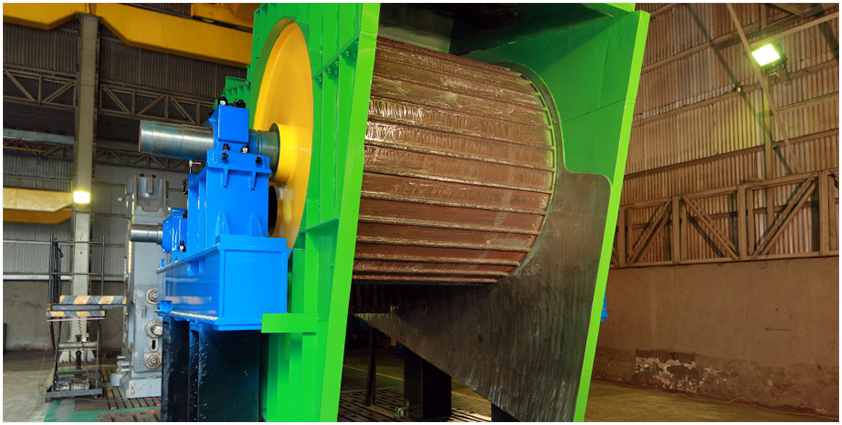

Cane Preparation

( capacity up to 25,000 TCD )

Overview

The Horizontal Fed Shredder is a cane preparation equipment which is installed before the mills or diffuser . the horizontal shredder is directly installed on main cane carrier , having an inclination up to 15 degrees .

A feeding drum is used to lift the whole stick or chopped cane from main cane carrier which feeds the cane between shredder rotor and anvil grid plate . by using the horizontal fed shredder following main benefits can be achieved ;

– 0% increase in cane preparation leads to 1% increase in extraction of first mill.

Salient features

High efficiency and high capacity

– Long fiber length with more open cells

– Cane preparation index 90 or more

– Better feeding of the mills

– Good combustion in the boilers

Proven technology

– Suitable to prepare long or chopped cane or mix of both.

– No need of cane knives before fiberizer.

– Can be installed on the existing cane conveyor.

– Easy to maintain.

Mechanical, operation & energy saving

– Capital investment for complete in-line fiberizer system is 10% to 20% less than conventional cane preparation system.

– Up to 20% energy saving in operation.

– Large swing dia. (1830 mm) to achieve 90 tip velocity with low rpm.

Flexible & Complete Offer

– A wide range of technical & design services to optimize cane preparation system to meet customers need.

– Portfolio includes a large range of various sizes.

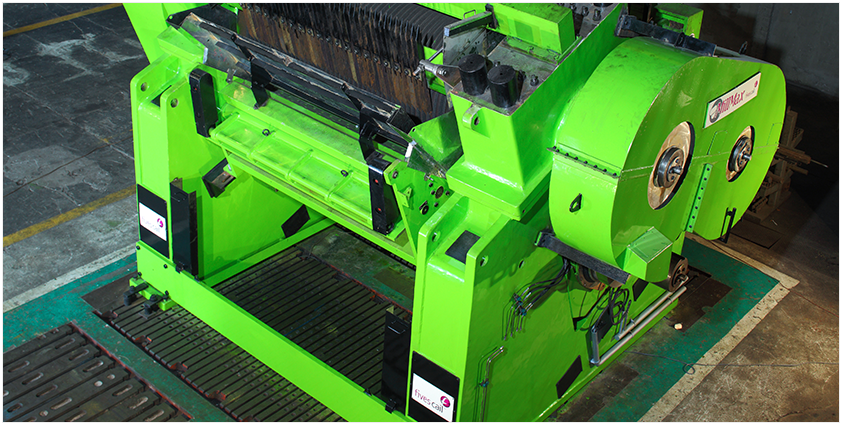

Cane Milling Equipment

( up to 35% reduction in energy consumption )

Overview

MillMax® is the latest generation of competitive equipment that limits juice re-absorption in bagasse during the sugar extraction process. It features with main two rollers and is positioned as a cost-effective solution for initial capital investment and ongoing operational expenses.

Salient features

Mechanical & Operation

– Low maintenance costs (no 3rd roll, no trash plate).

– Low installation costs (with existing drive to increase crushing).

– Robust, easy mill settings & operator friendly

– Bearing liners having integral water cooling system.

Anti-Reabsorption Device

– RLD device ensures the continuous compression of the bagasse at discharge to avoid reabsorption of juice.

Energy Saving

– Low power absorbed per ton fiber Up to 35% less power consumption.

Savings

– 25% less annual maintenance cost.

Cane Milling Equipment

( crushing capacity up to 25,000 TCD )

Overview:

This Mill is horizontally / vertically adjustable four roll equipment used to extract sugar cane juice. It is equipped with three Main Rolls ( floating top-roll, bagasse-roll and cane-roll ) and one heavy-duty 4th Roll.

Position of Feed and Discharge Rolls can be adjusted horizontally / vertically comparing to the axis of Top-Roll to allow the periodic adjustment of required openings. Vertical adjustment of Mill Rolls can be done using packing under their bearings. Position of 4th Roll can also be adjusted along two axis to cyclically set its opening with Top and Feed Roll.

Salient features

High efficiency and high capacity

– Large Bearing Journals to bear heavy loads.

– Easily convertible from 4-roll to 6-roll mill.

– Under feed roll directly engaged with feed roll

– All Mill Rolls are easily convertible to perforated type to maximize the juice drainage.

Ultimate & proven technology

– Continuous improvement based on bicentennial and global Expertise of the sugar industry

– Robustness and long-life of the steel frames analyzed with FEA

Easy maintenance & operation

– Easy horizontal adjustment of mill rolls

– Easy external adjustment of trash plate

– Floating type scraper for mill top roll

– New design mill bearings, steel housing and bronze liner both have independent water cooling system

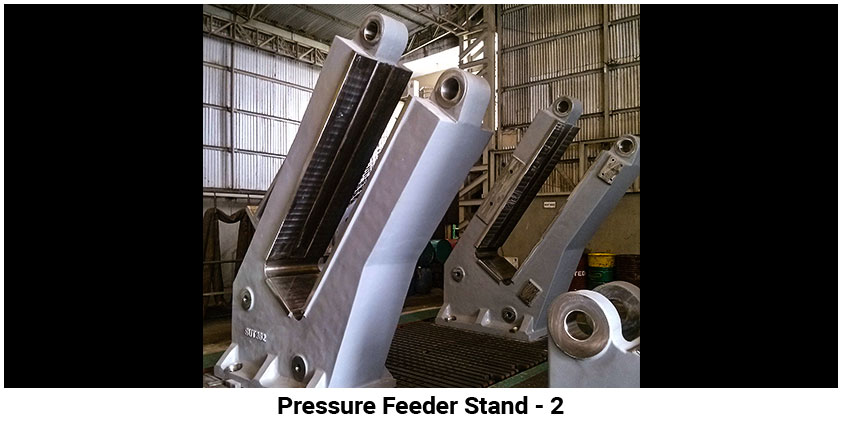

Cane Milling Equipment

( crushing capacity up to 25,000 TCD )

Overview:

This Mill is horizontally / vertically adjustable SIX roll equipment used to extract sugar cane juice commonly installed at position no. 1 in a milling tandem . It is equipped with three Main Rolls ( floating top-roll, bagasse-roll and cane-roll ) , two heavy-duty Pressure Feeder Rolls and one underfeed roll .

Position of Feed and Discharge Rolls can be adjusted horizontally / vertically comparing to the axis of Top-Roll to allow the periodic adjustment of required openings. Vertical adjustment of Mill Rolls can be done using packing under their bearings. Position of pressure feeder Roll can also be adjusted along the axis of pressure feeder stand to set its opening

Salient features

High efficiency and high capacity

– Large Bearing Journals to Bear Heavy Loads

– All Mill Rolls are easily convertible to perforated type to maximize the juice drainage.

– Wide range of design with

– Heavy Duty Pressure Feeder.

– Pinion or independent driven Pressure Feeder Rolls.

– Cast Iron Sixth Roll Shell.

– Medium Duty Pressure Feeder.

– Chain and Sprocket Driven Pressure Feeder. Rolls

– Steel Fabricated Sixth Roll Shell.

– Increased extraction compare to 4 Roll Mills .

Ultimate & proven technology

– Continuous improvement based on bicentennial and global Expertise of the sugar industry.

– Robustness and long-life of the steel frames analyzed with FEA.

Easy maintenance & operation

– Easy horizontal adjustment of mill rolls.

– Easy external adjustment of trash plate.

– Floating type scraper for mill top roll.

– New design mill bearings, steel housing and bronze liner both have independent water cooling system.

Cane Milling Equipment

Overview:

Designed to eliminate the undesirable effects of Tail-bar & Coupling arrangements. This allows for free floating of the Top Roller which in return has no axial load transmission to the gear. Manufactured in accordance to customer specific requirements & parameters in a variety of sizes.

Salient features

High mill efficiency

– MMC is designed to eliminate all the undesirable

effects of tail-bar and coupling arrangement.

– MMC allows free floating of Top Roll.

– No axial load transmitted to gear .

Proven technology

– Miss-alignment between Gear Shaft and Mill Top Roll due to alignment error in installations is fully

compensated by the MMC.

– MMC is the first choice to use with new generation of Gear.

– Mechanical & operation and safety

Easy to install

– Safe & smooth operation is guaranteed by back-up slings

– Competitive capital cost followed by low cost maintenance

Cane Milling Equipment

Overview:

The Moisture Control Unit is designed and installed on a 4-Roll Conventional Mill, which helps to reduce the bagasse moisture coming out from the discharge roll. This results in optimizing the juice extraction during the milling process by providing additional drainage of juice and reducing the final bagasse moisture ;

Salient features

High mill efficiency

– Separate Hydraulic Unit is equipped to control the limiting Device.

– Charged with its existing mill house hydraulic systems 2 Nos Hydraulic cylinders suitable of 220 Bar operating pressure.

– Flexible Pipe and valves along with gauge suitable for 220 Bar operating pressure.

Proven technology

– No separate Drive Power Requirements

– Can be installed to existing 4 Roller and 6 Roller Mills.

Mechanical & operation and safety

– Easy to install with minimum maintenance requirements.

– Low maintenance cost.

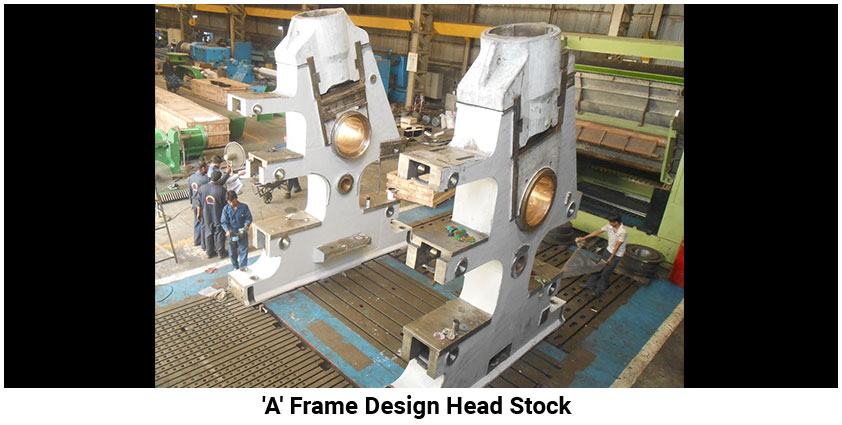

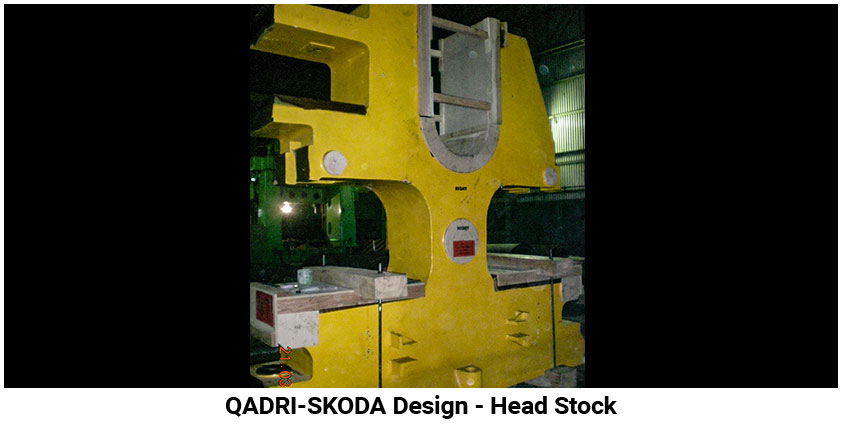

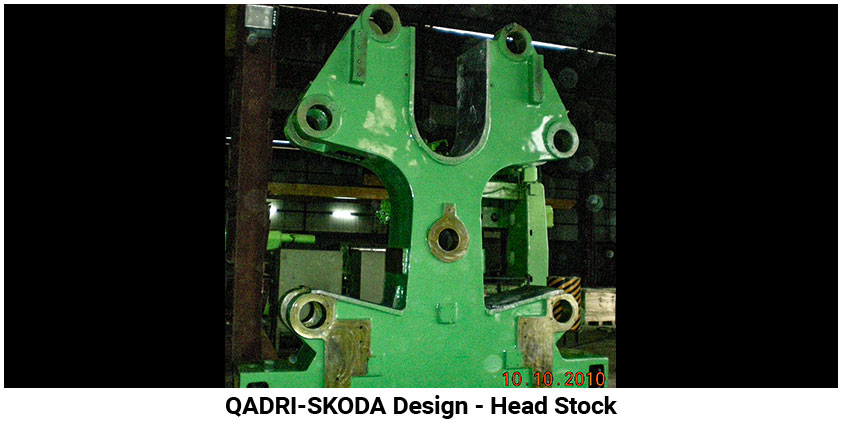

Spares

Overview:

Headstocks are designed using latest CAD & CAE software and casted in AISI 1045 ( normalized ) steel grade

Salient features

Design and Engineering

– Re-designed to suit your existing civil foundation

– Re-designed to suit your existing mill components

– Re-designed to achieve increased crushing capacity by accommodating large roll sizes

– Robust Head Stocks specially designed for heavy-duty operations •

Proven Technology

– Strength analysis to improve structure ( using FEA )

– Interference check analysis ( using Autodesk Inventor ® )

– Casting simulation and analysis ( using Magma Soft ® )

– Machined areas are tested by Ultrasonic Testing (ASTM A 609 Level 2)

– Non-machined areas are tested by Magnetic Testing (ASTM A709 & E125 Level 2).

Additional Services

– SS cladding on juice exposed areas of Head Stocks

– 12 ~ 30 mm thick cladding on mill bottom roll bearing seats

– 3 ~ 5 mm thick SS plate welded on interface to cover juice exposed areas

– Site Supervision of installation

Spares

Overview:

Top Caps are used to apply high ‘ hydraulic load ’ on Mill-Top Roll. Custom made ‘ Hydraulic Twin Sets ’ , made from special grade Nitrile Rubber / Neoprene , are used to avoid any pressure loss in it .

Salient features

Design and Engineering

– Robust Castings specially designed for heavy-duty operations

– Replaceable Bronze / SG Iron Sleeves

– High strength ‘ hydraulic twin sets ’

Proven Technology

– Strength analysis to improve structure ( using FEA )

– Casting simulation and analysis ( using Magma Soft ® )

– Pre-tested at our works at up to 6000 PSI

– Machined areas are tested by Ultrasonic Testing (ASTM A 609 Level 2)

Spares

Overview:

Side caps of cane crushing mill are casted in AISI 1045 ( normalized ) steel grade . it contains ‘ adjustment mechanism ’ to push and pull Bottom-Rolls and 4th Roll on horizontal axis to adjust mill openings .

Salient features

Design and Engineering

– Re-designed to suit your existing mill components

– Robust castings specially designed for heavy-duty operations

– Wide range of design options ;

– Fixed-type ( bolted with Head Stocks using two long bolts )

– Swivel-type ( designed for easy mount and dismount of Mill Bottom Rolls )

– In-built adjustment mechanism for of mill bottom and 4th rolls

Proven Technology

– Strength analysis to improve structure ( using FEA )

– Interference check analysis ( using Autodesk Inventor ® )

– Casting simulation and analysis ( using Magma Soft ® )

– Machined areas are tested by Ultrasonic Testing (ASTM A 609 Level 2)

– Non-machined areas are tested by Magnetic Testing (ASTM A709 & E125 Level 2)

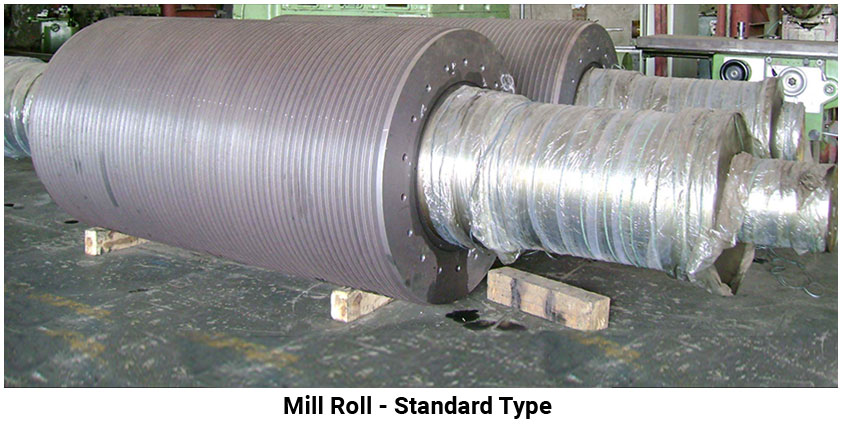

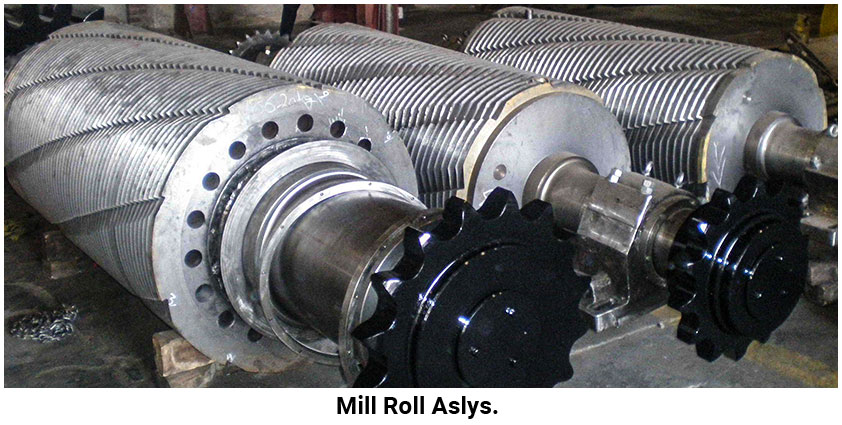

Spares

Overview:

Mill Roller contains a SHELL shrink mounted on forged Steel SHAFT . Shells are grooved to increase contact area with cane . Juice Flanges and Guards are used to prevent bagasse droppage and juice spills on to the Mill Bearings

Salient features

Flexible and complete offer

– Wide range of material available suiting your operational requirement ;

– SHELL : GREY CAST IRON ( BS1452 Grade 220 ) SHAFT :EN 8 / SAE 1045

– SHELL : SG IRON ( SG-40 / SG-50 ) SHAFT : EN 19 / SAE 4140

– SHELL : CAST STEEL ( SAE 1035 ) SHAFT : EN 14B

– SHELL : Qast-Alloy SHAFT : EN 3A

grey cast iron ‘specially’ engineered for

enhanced performance of sugar mill rolls

Proven Technology

– Strength analysis to improve structure ( using FEA )

– Forging of shaft is inspected by Ultrasonic Testing as per ASME V SA 388 ( Level 2 )

Hard – Facing , Arcing & Tear Drops

Specially designed roughening of mill rolls shells ;

– to reduce wear on shell

– to enhance bagasse grip for better extraction

Additional features

– messcheart and chevron grooves can be made as per customer’s requirement

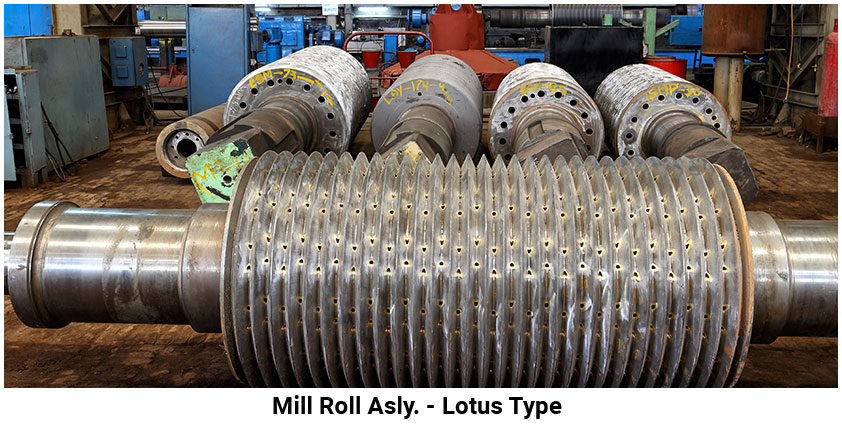

Spares

Overview:

Perforated type rolls are used for increased extraction of cane juice . Horizontal Juice drainage channels and small perforations are drilled perpendicular to the axis of juice drainage channels. Brass nozzles are then shrink fitted in these perforations .

‘ Double Angular ’ staggered orientation is used to equally spread perforation on the circumference of shell for smooth collection and drainage of juice during the extraction process .

Salient features

Enhanced Performance

– May increase juice extraction 1 ~ 2.5 %

– May decrease bagasse moisture 2 ~ 3 %

– Specially designed ‘ multi-hole ’ brass nozzles to avoid chocking ,

recommended for

– discharge roll of all mills

– top roll of the last mill

Flexible and complete offer

– Available re-designing facility of your existing standard roll into perforated mill roll

– Wide range of material available suiting your operational requirement ;

– SHELL : GREY CAST IRON ( BS1452 Grade 220 ) SHAFT : EN 8 / SAE 1045

– SHELL : SG IRON ( SG-40 / SG-50 ) SHAFT : EN 19 / SAE 4140

– SHELL : CAST STEEL ( SAE 1035 ) SHAFT : EN 14B

– SHELL : Qast-Alloy SHAFT : EN 3A

grey cast iron ‘specially’ engineered for

enhanced performance of sugar mill rolls.

Proven Technology

– Strength analysis to improve structure ( using FEA )

– Forging of shaft is inspected by Ultrasonic Testing as per ASME V SA 388 ( Level 2 )

Hard – Facing , Arcing & Tear Drops

Specially designed roughening of mill rolls shells ;

– to reduce wear on shell

– to enhance bagasse grip for better extraction

Spares

Overview:

Proof machined and fully-machined shell castings to be shrink-fitted at customer’s site .

Salient features

Flexible and complete offer

– Option of Proof Machined or fully-machined Mill Roll Shells

– Fully machined Perforated Mill Roll Shells comes with pre-fitted brass nozzles

– Wide range of material available suiting your operational requirement ;

– GREY CAST IRON ( BS1452 Grade 220 )

– SG IRON ( SG-40 / SG-50 )

– CAST STEEL ( SAE 1035 )

– Qast-Alloy

grey cast iron ‘specially’ engineered for

enhanced performance of sugar mill rolls

Hard – Facing , Arcing & Tear Drops

Specially designed roughening of mill rolls shells ;

– to reduce wear on shell

– to enhance bagasse grip for better extraction

Additional features

– messcheart and chevron grooves can be made as per customer’s requirement

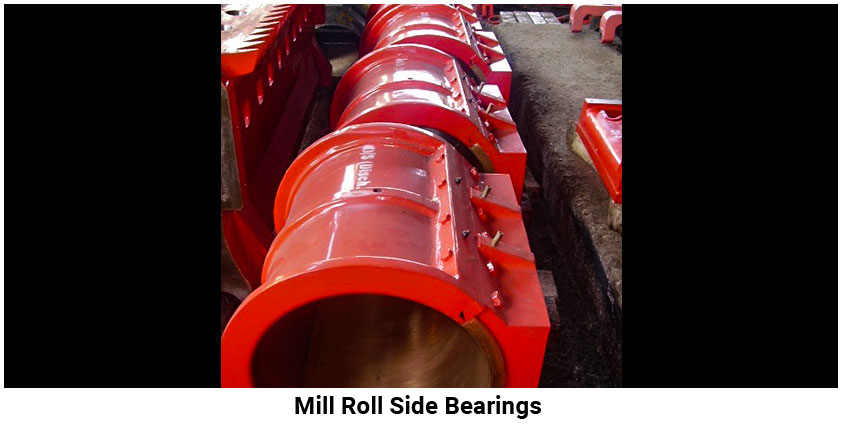

Spares

Overview:

Mill Roll Bearing helps Mill Roll to rotate smoothly using high viscosity synthetic / bitumen oil which reduces the friction between liner and shaft. Mill Roll Bearing composite design type with Cast Steel bearing housing and bronze liner.

Salient features

INNOVATIVE DESIGN

– Customized manufacturing according to customers requirement.

– Water-cooled design liners for Mill Roll Bearings

– Steel housing and bronze liner both can have the independent water-cooling system

WIDE RANGE OF MATERIALS

– BS 1400 : LG-2

– BS 1400 : LG-4

– BS 1400 : PB-1

– BS 1400 : PB-2

– SAE-64

– SAE-65

– SAE-67

FLEXIBLE AND COMPLETE OFFER

– Available re-designing facility for your existing bearings to the new innovative design

– Addition of advance sealing arrangement to prevent oil leakage and contamination

Spares

Overview:

Mill Crown pinions are exclusively designed and simulated to run smoothly on customers provided mill settings . Computer aided design software is used to draw proper involute profile of Mill Crown Pinions to ensure more rolling and less sliding . Mill Crown Pinions are fully machined and ultrasonically tested as per customer’s requirement

Salient features

DESIGN SIMULATION PROCESS

– Engineered using simulation software to evaluate the tooth profile and smooth operation at minimum and maximum working centers

SMOOTH PROFILE

– Tooth profile fully machined to achieve precision & smoothness

HEAT TREATMENT

– PLC controlled heat treatment facility helps to ensure execution of required heat treatment cycle to achieve the required mechanical properties

INDUCTION HARDENED

– Tooth profile induction hardened with latest state of the art technology to increase wear resistance

FLEXIBLE & COMPLETE OFFER

– Available re-designing facility to redesigning according to customer’s requirements A wide range of materials available for your choice ( like ; AISI 1045 ; AISI 4140 ; AISI 4340 …. etc. )

Spares

Overview:

Scraper and Trash plates are casted and fully-machined according to customer’s required profile.

Salient features

Flexible and complete offer

Wide range of material available suiting your operational requirement ;

– Cast Steel to AISI 1045

– Cast Steel to AISI 1030

– Cast Steel to AISI 1035

– SG IRON ( SG-40 / SG-50 )

Pre Hard-facing

– Option available for fully machined , pre hard-faced and ready to assemble Trash Plates

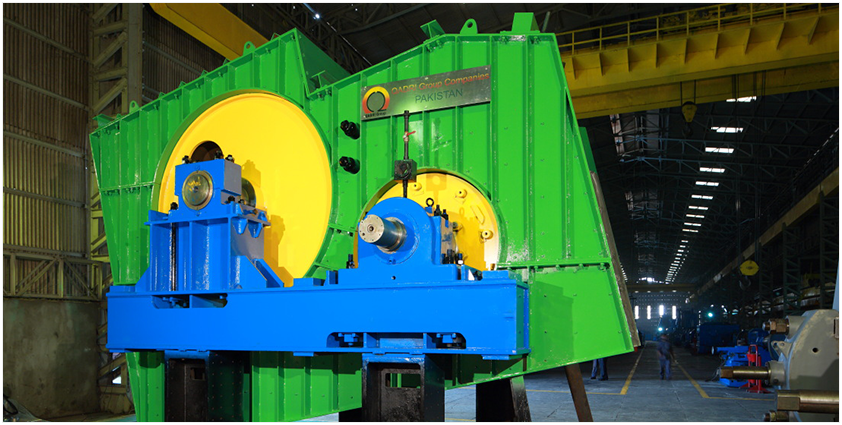

Spares

Overview:

Shredder Rotors are designed and manufactured to achieve required cane preparation by separating and opening the cell wall efficiently

Salient features

Flexible and complete offer

– Wide range of technical services available to optimize performance

– Wide range of sizes and designs

– Hard-facing of Shredder Palms ( Discs ) and Hammers

– Static balancing of Shredder Palms ( Discs ) and Hammers before assembly

– Custom made robust design Plummer Blocks ( designed to host standard SKF bearings )

Proven Technology

– Forging of shaft is inspected by Ultrasonic Testing as per ASME V SA 388 ( Level 2 )

– Dynamic balancing of shredder Rotors as per ISO 1940/1 – G 6.3

Spares

Overview:

SHAFTS are hot forged , dehydrogenated ( fully killed ) , Heat treated ( normalized or Quenched & tempered ) , rough machined , Ultrasonically tested and fully machined as per customer’s requirement .

Salient features

Flexible and complete offer

Wide range of materials available suiting your operational requirement ;

– EN 8 / SAE 1045

– EN 19 / SAE 4140

– EN 14B

– EN 3A

Proven Technology

– Forging of shaft is inspected by Ultrasonic Testing as per ASME V SA 388 ( Level 2 )

– Complete MTC and Heat treatment reports

Spares

Overview:

Diffuser Head Shafts are hot forged , dehydrogenated ( fully killed ) , Heat treated ( normalized or Quenched & tempered ) , rough machined , Ultrasonically tested and fully machined as per customer’s requirement .

Salient features

Flexible and complete offer

– Wide range of materials available suiting your operational requirement ;

– EN 8 / SAE 1045

– EN 19 / SAE 4140

– Complete with pre-shrink fitted sprockets with induction hardened teeth

Proven Technology

– Forging of shaft is inspected by Ultrasonic Testing as per ASME V SA 388 ( Level 2 )

– Complete MTC and Heat treatment reports

Spares

Overview:

Single piece casted and machined according to the customer’s requirement . Working areas are inspected by Ultrasonic testing and teeth cut to international standard .’ Tooth flanks are induction hardened to achieve high performance and increased service life .

Salient features

Flexible and complete offer

– Wide range of materials available suiting your operational requirement ;

– AISI 4140 / AISI 4340

– AISI 8640

– Wide range of Gear Types

– Spur Gear

– Single Helical Gear

– Double Helical Gear

– Wide range of Size

– up to 6 meters outer diameter

– up to 42 mm module

Proven technology

– Strength analysis to improve structure ( using FEA )

– Gear Calculation ( using Autodesk Inventor ® )

– Casting simulation and analysis ( using Magma Soft ® )

– Machined areas are tested by Ultrasonic Testing (ASTM A 609 Level 2)

– Non-machined areas are tested by Magnetic Testing (ASTM A709 & E125 Level 2)

Additional Features

– Induction Hardening of Tooth Profile

– Site Installation

Services

Overview:

Qadri Group offers numerous types of ‘Engineering Studies ’ by Fletcher’s trained technical experts to certify enhancement in overall performance

Sugar Mill Performance Audit

– Mill House Performance Audit

– Process House Performance Audit

– Designing and establishing protocols for operations

– Designing and establishing protocols for maintenance

Mill House Capacity Enactments

– Evaluation of existing equipment to gage potential of improvement

– Evaluation of existing equipment to gage potential of modifications

– Recommendations on mid-term and long term plans for new equipment installations

Revamping of existing equipment

– Engineering studies and design to revamp existing components , for example ;

– Conversion of Standard Mill Roll into Perforated Mill Roll

– Replacement of conventional Tail Bar and Coupling drive into modern Multi Miss-alignment Coupling

– Conversion of existing Mill Roll Bearings into Modern composite design mill roll bearings with dual water cooled liners and housings

– Installation of sealing system on existing Mill Rolls bearings to prevent foreign contamination in lubricant

Services

Overview:

Qadri Group specialized in refurbishing and repairing of equipment for the sugar industry.

Headstock Replacement Services

– study of existing HEADSTOCK design to identify weak areas in accordance to the new crushing requirements

– re-designing of new HEADSTOCK includes the following aspects ;

– to be installed on existing civil foundation without changing the Foundation bolts c/c

– to suit the existing Mill Components ( bearings , Rollers … etc. )

– to achieve service factor of 1.7 or above by using long years of experience and FEA

– to accommodate large size Roller to increase crushing capacity

Re-shelling of Mill Roll Shafts

– FLEXIBLE AND COMPLETE OFFER

– Available re-designing facility of your existing conventional roll to perforated mill roll

– Wide range of shell materials available suiting your operational requirements

– NDT inspection of the old shaft

– Refurbishment of mill roll shaft ( bearing journals , square-end , keyways ,…etc. )

– Heat treatment of shaft in PLC furnace ( in case of refurbishment )

– DOOR-TO-DOOR SERVICE

– One-stop solution for mill roll collection, shipping and re-shelling

Refurbishment of Gear Wheels

– FLEXIBLE AND COMPLETE OFFER

– Dimensional and NDT inspection of the old Gear Wheel

– Re-teeth cutting to remove pitted / worn out surface on tooth flanks

– Induction hardening of tooth flanks

– Maintaining the same center distance by re-designing the mating pinion

Services

Overview:

Qadri Group provides comprehensive on-site services to Sugar Industry

NDT Services

– Complete Range of on-site NDT Services ;

– Dye Penetrant Testing

– Magnetic Particle Testing

– Ultrasonic Testing

– Dimensional and geometrical inspection

Reverse Engineering

– Reverse engineering of existing worn-out components by our team of experienced Design and QA engineers

– Product development through Faro Scan Arm and 3D scanners

– FEA analysis

– Preparation of complete manufacturing drawings

Erection and Commissioning

– Site-Erection supervision of Sugar Mill Equipment by team of Fletcher’s trained erection engineers

– Commissioning of Sugar Mill Components to achieve the optimum performance level

– Designing and establishing protocols for smooth operations

(+92 42-111-172-374)

(+92 42-111-172-374)