Pioneers in plant and equipment manufacturing

Unmatched products for the sugar industry

For over half a century, we have been supplying top of the line equipment for the sugar industry to small, medium and large manufacturers around the globe. With our experience and expertise of the sugar manufacturing sector, we also provide our customers with turnkey solutions and consultancy to help enhance their operations, increase productivity and minimize costs. With over 100 years of engineering experience and expertise, Qadri Group is the right choice when it comes to setting up or upgrading your sugar manufacturing operations anywhere in the world.

Technology Partners

FRANCE Technology Partner Sugar

CZECH REPUBLIC Technology Partner Sugar

Services We Offer to the Sugar Sector

Qadri Group is a trusted name in the global sugar processing equipment industry. We not only produce state of the art equipment and products but provide complete turnkey solutions, consultancy and project management to help our clients enhance and maximize their manufacturing efficiency.

Consultancy

With our knowledge of the global sugar manufacturing industry, we are able to help our clients identify critical issues and realize opportunities that ensure growth.

Plant Upgradation

By providing top of the line equipment, products and spares, we can help you set up new or upgrade your existing sugar manufacturing operations to outmatch your competition.

Case Studies

Using our experience, knowledge and key insights from successful projects in the past, we can guarantee success by applying valuable findings from similar projects.

Customers and Partners around the Globe

Throughout our years of service, we have established technical partnerships and clientele with some big names in the global sugar manufacturing industry. These partnerships are crucial to guarantee that our clients get the best possible service.

Equipment

Cane Juice Preparation

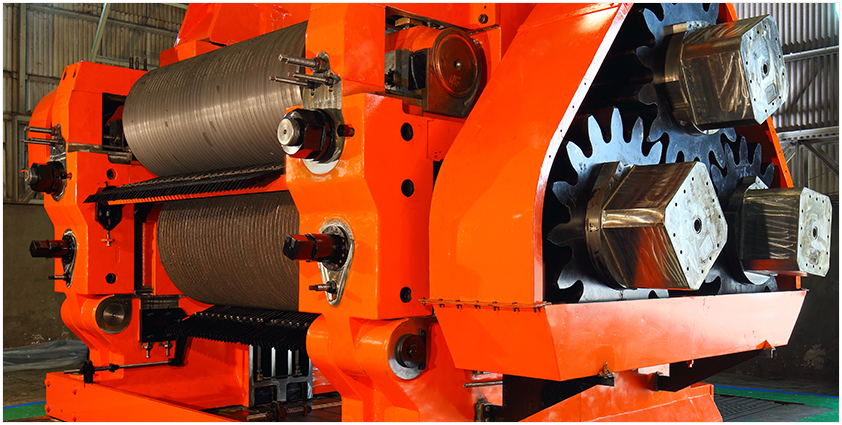

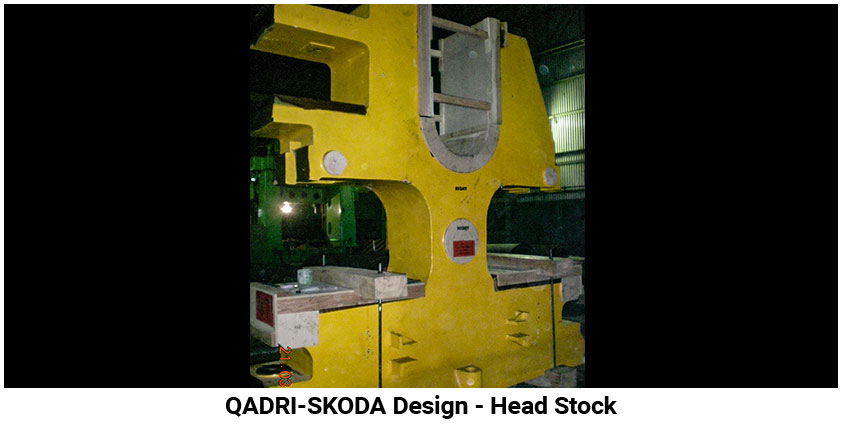

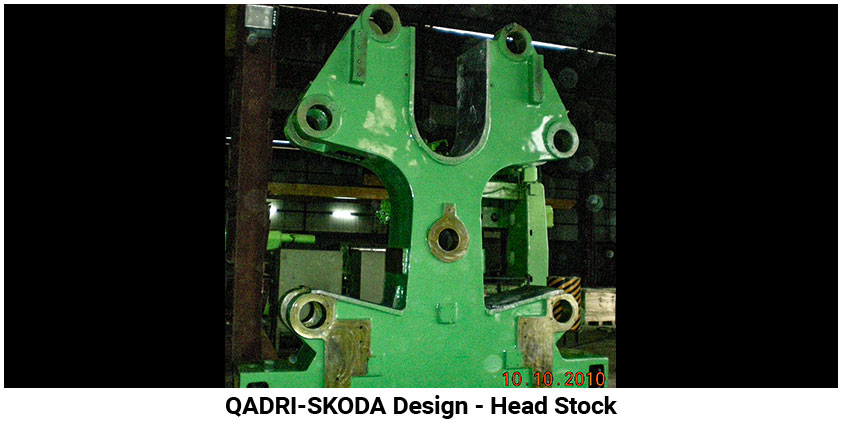

Qadri Skoda Design

(Capacity up to 25,000 TCD)

High efficiency and high capacity

- Excellent fiber particle size distribution

- Extremely robust fabricated assembly

- Better feeding of the mills

- Excellent cane preparation index (90+)

- Improved final bagasse moisture

- Consistent higher bagasse density

- Lower bagasse pol loss

Proven technology

- Fine preparation by separating the fibers and opening the cell wall efficiently

- Excellent juice extraction at each stage of extraction process

- Increases bulk density of the prepared cane, thereby increasing the capacity of the extraction plant

- Easy to maintain

Mechanical and cost effective

- Cost effective & reliable solution

Flexible & Complete Offer

- A wide range of technical & design services available to optimize cane preparation system to meet customer’s need

- Portfolio includes a large range of shredder size

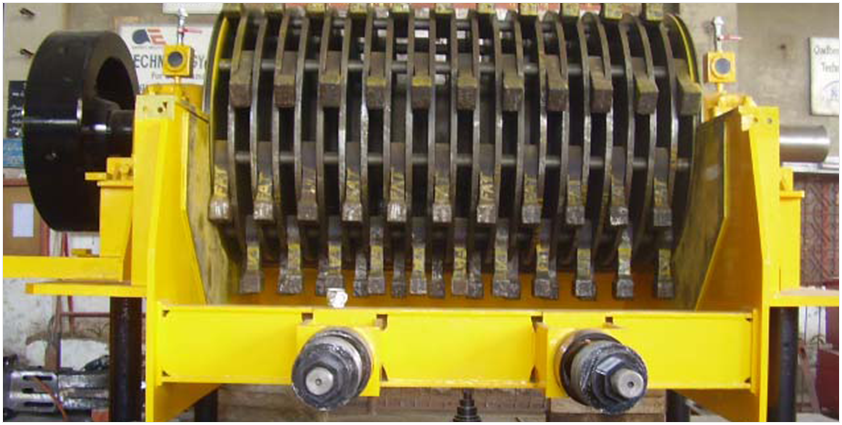

Cane Juice Preparation

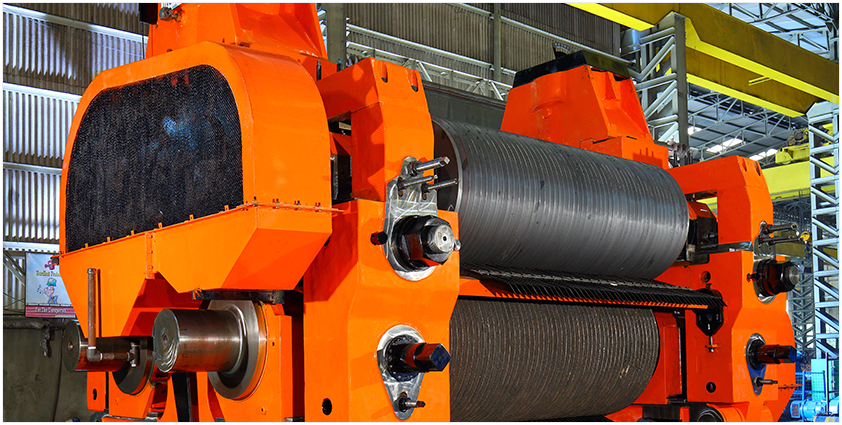

COP-10 Brazilian Type (Heavy Duty)

1% increase in cane preparation leads to 0.1% increase in the extraction of first mill

High efficiency and high capacity

- Long fiber length with more open cells

- Cane preparation index 90 or more

- Better feeding of the mills

- Good combustion in the boilers

Proven technology

- Suitable to prepare long or chopped cane or mix of both

- No need of cane knives before fiberizer

- Can be installed on the existing cane conveyor

- Easy to maintain

Mechanical, operation & energy saving

- Capital investment for complete in-line fiberizer system is 10% to 20% less than conventional cane preparation system

- Up to 20% energy saving in operation

- Large swing dia. (1830 mm) to achieve 90 tip velocity with low rpm

Flexible & Complete Offer

- A wide range of technical & design services to optimize cane preparation system to meet customers need

- Portfolio includes a large range of various sizes

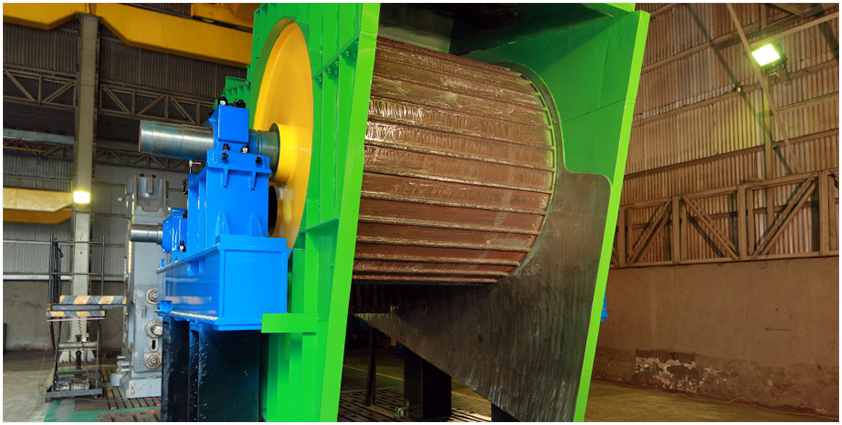

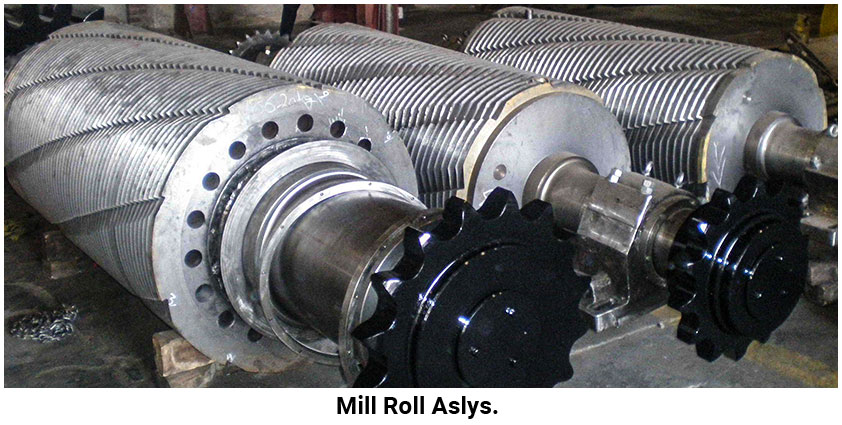

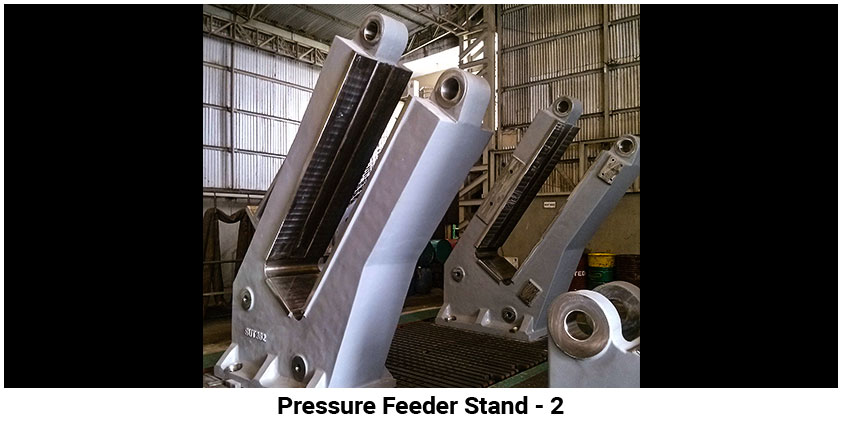

Cane Juice Extraction

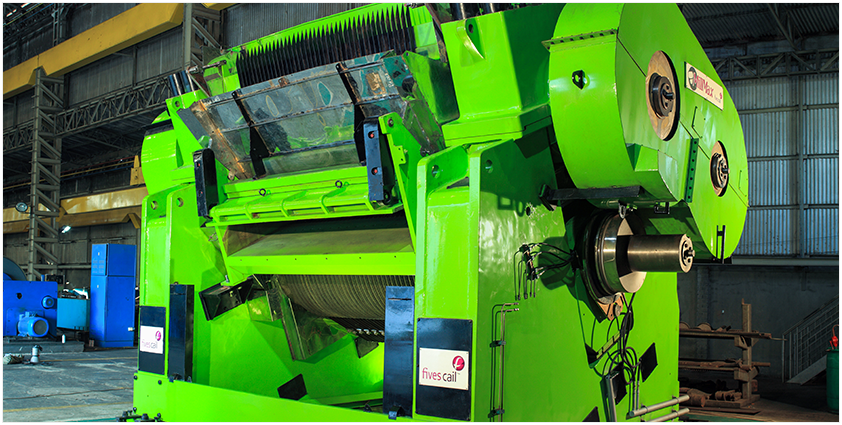

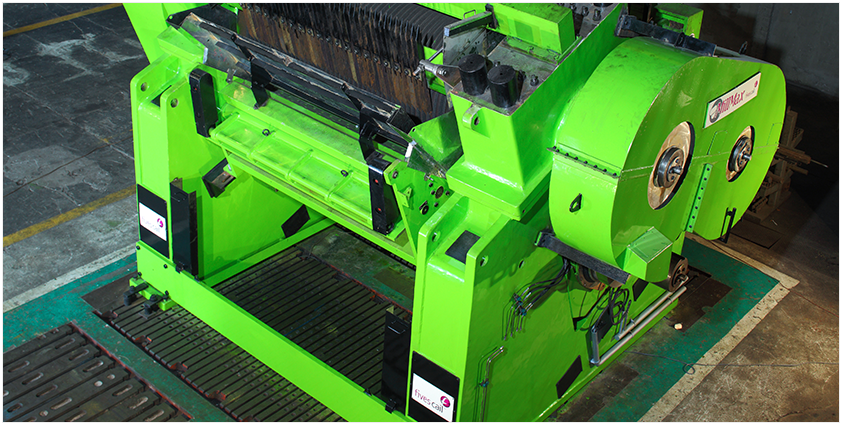

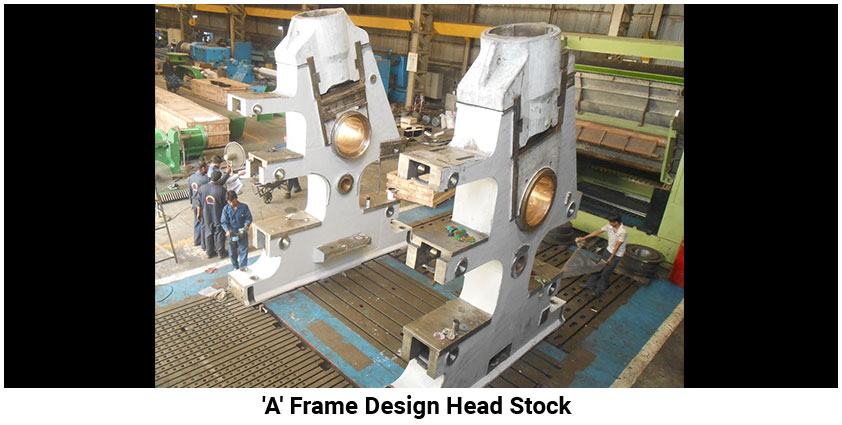

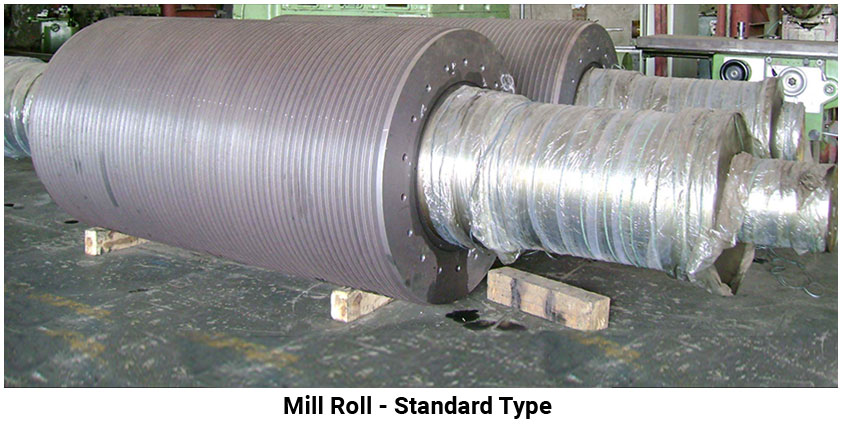

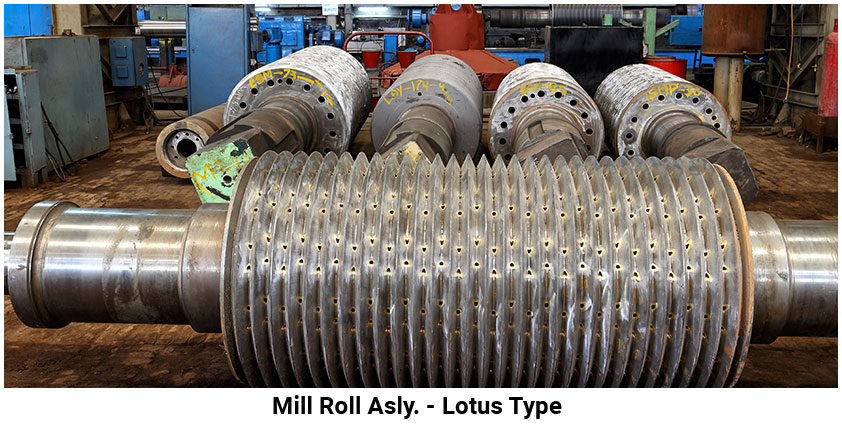

55” x 110” 4-Roll Mill

(Crushing capacity up to 25,000 TCD)

High extraction efficiency and high capacity

- Large bearing journals to bear heavy loads

- Easily convertible from 4-roll to 6-roll mill

- Under feed roll directly engaged with feed roll

- All mill rolls are easily convertible to perforated type to maximize the juice drainage

Ultimate and proven technology

- Continuous improvement based on bicentennial and global expertise of the sugar industry

- Robustness and long-life of the steel frames analyzed with FEA

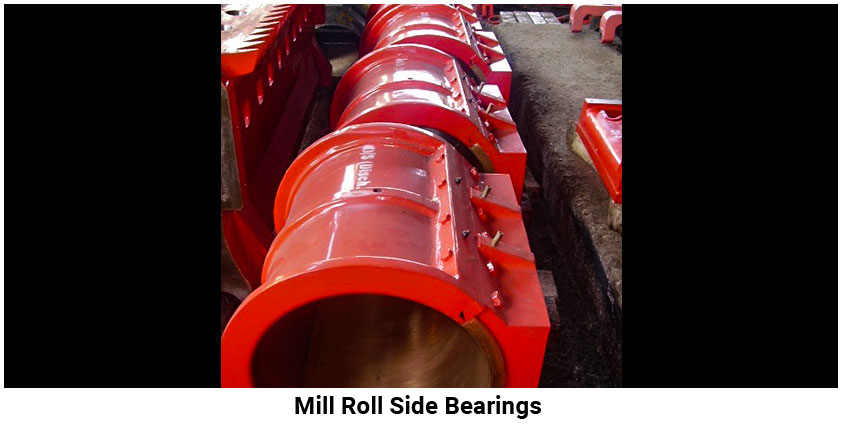

Easy maintenance and operation

- Easy horizontal adjustment of mill rolls

- Easy external adjustment of trash plate

- Floating type scraper for mill top roll

- New design mill bearings, steel housing and bronze liner both have independent water cooling system

Flexible and complete offer

- A wide range of technical & design services to optimize mill according to customer’s need

- Portfolio includes a large range of mill sizes

- Tailor-made consultancy according to customer’s need

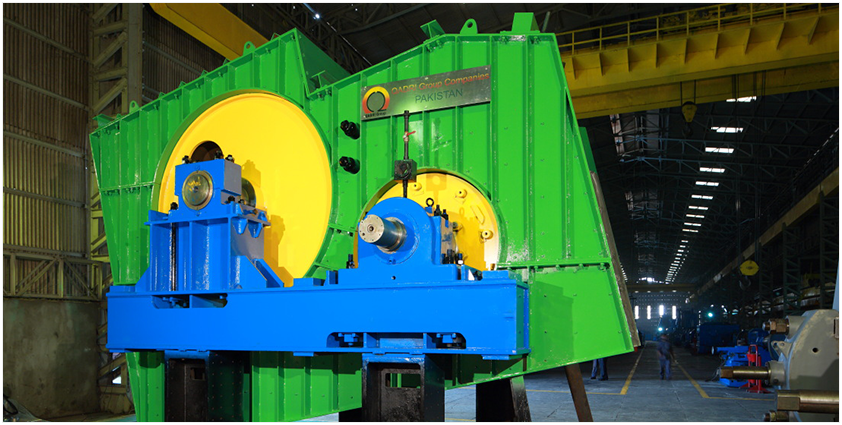

Cane Juice Extraction

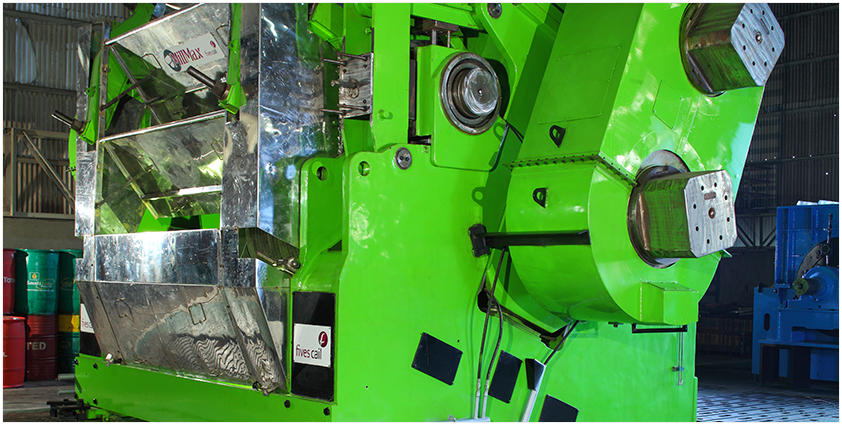

(Up to 35% reduction in energy consumption)

Process

- Good extraction and final bagasse humidity achievable

Mechanical & Operation

- Low maintenance costs (no 3rd roll, no trash plate)

- Low installation costs (with existing drive to increase crushing)

- Robust, easy mill settings & operator friendly

- Bearing liners having integral water cooling system

Anti re-absorption device

- RLD device ensures the continuous compression of the bagasse at discharge to avoid re-absorption of juice

Energy saving

- Low power absorbed per ton fiber

- Up to 35% less power consumption

Savings

- 25% less annual maintenance cost

- Portfolio includes a large range of mill sizes

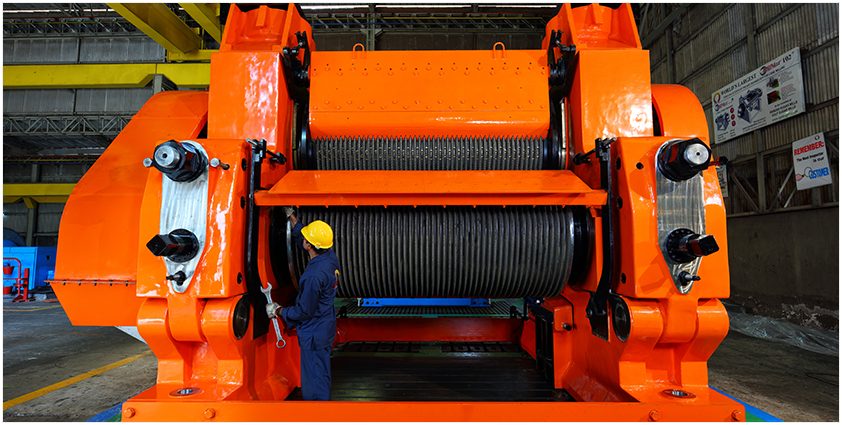

Cane Juice Extraction

(Easy Installation and Low Cost of Maintenance)

High mill efficiency

- MMC is designed to eliminate all the undesirable effects of tail-bar and coupling arrangement

- MMC allows free floating of top roll

- No axial load transmitted to gea

Proven technology

- Misalignment between gear shaft and mill top roll due to alignment errors in installations is fully compensated by the MMC

- MMC is the first choice to use with new generation of gear

Mechanical, operation and safety

- Easy to install

- Safe & smooth operation is guaranteed by back-up slings

- Competitive capital cost followed by low cost maintenance

Flexible & complete offer

- A wide range of technical & design services available to optimize mill drive system to meet customer’s need

- Portfolio includes a large range of MMC sizes

(+92 42-111-172-374)

(+92 42-111-172-374)